Rotomolded Food Grade Products

Granger Plastics Company has been rotationally molding certified prime virgin materials since the inception of the company. Because of Granger’s stance of not running any off-grade or “wide-spec” materials, coupled with Granger’s on-going pursuit of high-quality, Granger is the perfect candidate for your food application rotational molding needs! Using USDA/FDA certified prime virgin materials for food contact, Granger can successfully take your food product or food processing product from start to finish by assisting with the rotational molding design to ensure it’s moldability, build your tooling or oversee the completion of your tooling and then take it right through production! Even stock product and drop ship to your facilities around the World if that is what your operation requires!

While polyethylene is the most common material for the rotational molding process, Granger has also found that polypropylene is a great fit for a number of rotomolded food grade applications because of its enhanced abrasion resistance and its ability to withstand elevated temperatures. Granger Plastics also has partnerships with other companies who have the ability to enhance the physical properties of molded components in a secondary process which will give the products superior strength and able to withstand elevated temperatures. Some food applications require heavy wall polypropylene parts, which Granger Plastics was capable of molding at unprecedented wall thickness levels that were never previously experienced by many experts in the rotomolding industry.

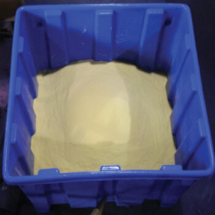

Food Grade Bulk Storage Bin

Granger Plastics also touts an ability to hold tighter tolerances than most of the rotational molding industry’s accepted standards. This allows Granger to be successful in working with many companies on converting products to the rotational molding process such as stainless steel. Being able to convert a product or component from stainless steel to a polymer based product allows for substantial savings and process improvements for a growing number of customers.

With Granger Plastics offering a complete single source rotational molding supply operation, complete with in-house molds, secondary trim & assembly, packaging and drop shipping, it continues to make since why Granger Plastics Company should be your partner in rotational molding.

Rotomolded Food Products Photo Gallery

Click any of the Custom Rotomolded Product Images Below for them to open in a larger lightbox gallery.

Rotomolded Food Products Links

Request Granger Plastics Information

Rotomolding Information

Granger Plastics on Facebook

Granger Plastics Company

The Granger Plastics Company

"Solutions Beyond Expectations"

Red Shift Daily Covers Rotomolded All Weather Traction Device, 'Weight-Mates'

... See MoreSee Less

Red Shift Daily - Science, Space, Tech News

redshiftdaily.com

We curate and deliver only the best and latest progress in space technology and discovery so you too can share in the excitement.- likes 0

- Shares: 0

- Comments: 0

0 CommentsComment on Facebook

Digital Journal publishes "Inclement Winter Weather Has Drivers Scrambling for Rotomolded All-Weather Traction Device"

... See MoreSee Less

Inclement Winter Weather Has Drivers Scrambling for Rotomolded All-Weather Traction Device

bit.ly

Winter storms terrorize drivers across the country, leaving many looking for ways to help keep their pick up trucks on the road. An Ohio Rotational Molding company may have the answer many are looking...0 CommentsComment on Facebook

Sandsaver Beach Erosion Solution helps 5 star resort, Swahili Beach win internationally recognized World Travel Awards for Africa's Leading Beach Resort 2023.... by naturally rebuilding the resorts beach!

Congratulations Swahili Beach!After installing Sandsaver at their resort on the Indian Ocean, Swahili Beach Resort wins the World Travel Awards for Africa's Leading Beach Resort 2023 at the awards show in Dubai, UAE this week.

Congratulations to Swahili Beach!!!

... See MoreSee Less

0 CommentsComment on Facebook

Granger Plastics on Twitter

Ohio has had 56 confirmed tornadoes so far this year leaving some residents scared and looking for ways to protect themselves and their loved ones. Tornado shelters or safe rooms are one of those ways. @SpectrumNews1OH @GrangerPlastics #Tornado

.

Inclement Winter Weather Has Drivers Scrambling for Rotomolded All-Weather Traction Device

#rotomolding #traction #winterweather #weightmates #grangerplastics #rotationalmolding #plastics

https://bit.ly/47DrZvp

Learn all about Rotational Molding..

https://rotationalmolding.com/rotational-molding.html

#rotomolding #rotationalmolding #plastics #manufacturing #molding #rotomoulding

Understanding The Basics of Rotomolding

#rotomolding #rotationalmolding #plastics #rotomoulding #molding #plastics #roto #grangerplastics #lldpe #hdpe

Understanding the Basics of Rotational Molding - Allizine

The process of rotational molding, also known as rotomolding, has been used for several decades now to manufacture ...

bit.ly

Granger Plastics On Instagram

May the Fourth Be With You... Protecting you from Mother Nature`s FORCE!

#tornado #tornadoshelters #plastics #grangeriss #stormshelters #rotomolding #rotationalmolding #grangerplastics #grangeriss #starwars #darthvader #stormtrooper #staysafeoutthere

In case you needed a "sign" to stay out of Jail... Here it is!

#rotomolding #laundrycarts #materialhandling #laundry #commerciallaundry #uniforms #towels #jail #CountyJail #Prison #plastics #inmates #getoutofjailfreecard

Sandsaver installed on an intracoastal waterway on the Gulf of Mexico producing positive results in a low tide environment!!

#Beach #beachErosion #BeacherosionSolution #Beaches #beachlife #Sandsaver #GrangerPlastics #GrangerPlasticsCompany #rotomolding #plastics #erosion #erosioncontrol

The Sandsaver by Granger Plastics continues to demonstrate unambiguously positive results as a natural beach erosion solution.

As you can see in this series of (4) before and after pictures, it is wildly evident that the Sandsaver has accreted tens of thousands of cubic yards of sand, while increasing the width profile both North and South of the system. If you look into the foreground of the pictures you will notice an amazing increase of sand, South of the installation site.

#Beach #beacherosionSolution #beaches #beacherosiontreatment #naturalSolutionToBeachErosion

#Sandsaver #plastics #rotomolding #rotomoulding #grangerplastics #Africa

One of the video clips from the Granger ISS debris impact test at Texas Tech University`s Wind Lab performing the FEMA 320 and FEMA 361 debris impact test.... If you`re considering purchasing ANY tornado shelter or storm shelter... Ask to see the debris impact test video... If they don`t or won`t show you, run away and find a reputable supplier who will!!! #tornado #tornadoshelters #StormShelters #GrangerISS #plastics #rotomolding #rotationalmolding #grangerplastics #plastics #weather #environment #emergency #FEMA #disaster #prepared #survival #Ohio #Texas #texastech

The Sandsaver continues to produce amazing results after only 6 weeks- over 20,000 cubic yards of sand accumulated and over 100` of increased width profile in some areas already!! #beacherosionSolution #beacherosion #beaches #plastics #rotomoulding #rotationalmolding #environment #beachconservation #stopbeacherosion #reversebeacherosion #savethebeaches #Sandsaver #grangerplastics #Ohio #Africa #Kenya #UnitedStates

See the Sandsaver Beach Erosion solution get installed and produce significant positive results at the beautiful @swahilibeach resort in Diani Beach Kenya in just 2 weeks! Video link in bio!

#Beach #beacherosionSolution #beaches #beacherosion #stopbeacherosion #dredgingalternatives #reversebeacherosion #Kenya #Africa #environment #tourism #travel #seetheworld #luxuryresort #resorts #dianibeachkenya #dianibeach #Sandsaver #grangerplastics #rotomoulding

Granger ISS Tornado Shelter installed at an incredibly beautiful horse farm in Southern Pines, North Carolina.

One of the rotomolding industry`s best innovations, ever.

#GrangerISS #tornadoshelters #StormShelter #tornado #tornadowarning #weather #plastics #rotomolding #rotationalmolding #grangerplastics #rotationalmoldingdotcom #Granger #NorthCarolina #Ohio

A photo of the tide coming in at the Sandsaver installation location at Diani Beach in Kenya... So incredibly beautiful... #Beach #BeachRenourishment #beacherosionSolution #Sandsaver #rotomolding #rotationalmolding #Granger Plastics #Africa #Kenya #dianibeach

The Sandsaver, a natural solution to beach erosion gains it`s second install, this time on private property located on the Gulf of Mexico 🇲🇽! In less than 10 weeks, in an extremely low tide environment, The Sandsavers are over 50% buried in Sand and have a generous amount of accretion between the modules and the surf. Behind the modules is starting to fill in creating a nice gradual slope. The property owner is ecstatic with the current progress and cant wait to see the beach completely rebuilt naturally by Sandsaver, another #rotomoulding innovation from Granger Plastics Company!

#Sandsaver #naturalSolutionToBeachErosion

#Beach #beaches #dredgingalternatives #BeachRenourishment #Florida #Texas #NorthCarolina #SouthCarolina #California #Alabama #Georgia #Virginia #Maryland #delaware #NewJersey #newyork #rhodeisland #massachusetts #Maine #California #Oregon #washingtonstate #savethebeaches #savetheoceans #rotomolding #rotationalmoldingproducts #rotationalmolding #plastics

Congratulations and a very special thanks to Hall of Fame Announcer for the @reds, Marty Brennaman who is calling his last home game after 46 incredible years for the Cincinnati Reds! You will be missed Mr. Brennaman!!! Pictured is EJ, the daughter of Granger Plastics` GM. EJ also doubles as our in-house baseball expert, who was lucky enough to get this photo with Marty earlier in the season. Now shes trying to figure out how to get it signed!! #MLB #Baseball #CincinnatiReds #Cincinnati #Ohio #MartyBrennaman #GrangerPlastics #Rotomolding #Plastics #HallOfFame #Retirement

America`s leading underground tornado shelter, The Granger ISS in full production... The only Tornado Shelter with a 500+ year lifespan... #Tornado #tornadoshelters #StormShelters #GrangerISS #HowToSurviveATornado #RotationalMoulding #Rotomolding #GrangerPlastics #RotationalMolding #Survival #preparedness #savealife #ohio